D&R Insights: Latest ASI Chain of Custody data indicates significant increase in CoC Material Flow year on year

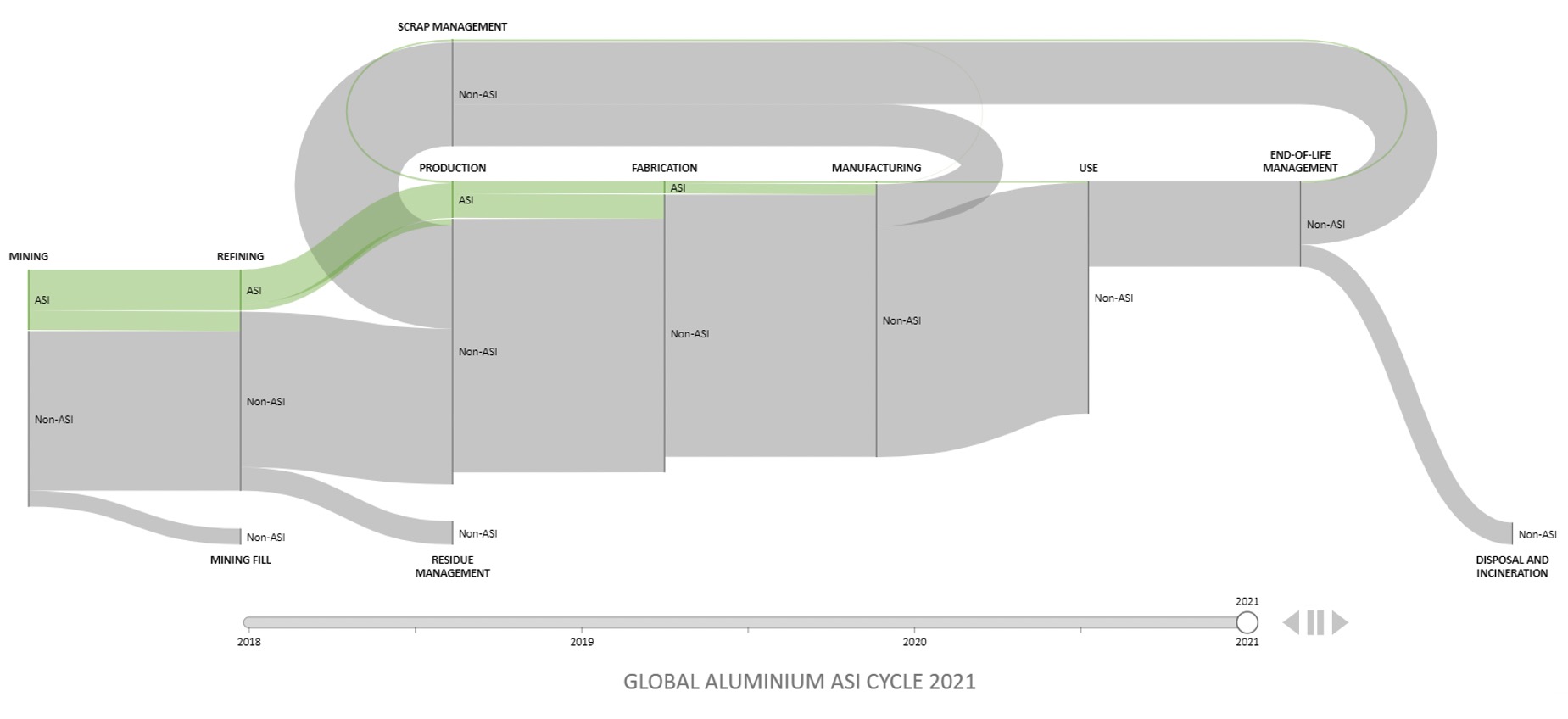

In data collected from ASI Chain of Custody (CoC) Certified Entities, ASI continues to record an increase in volumes of ASI CoC Material along the full value chain with substantial increase downstream.

27 July 2022

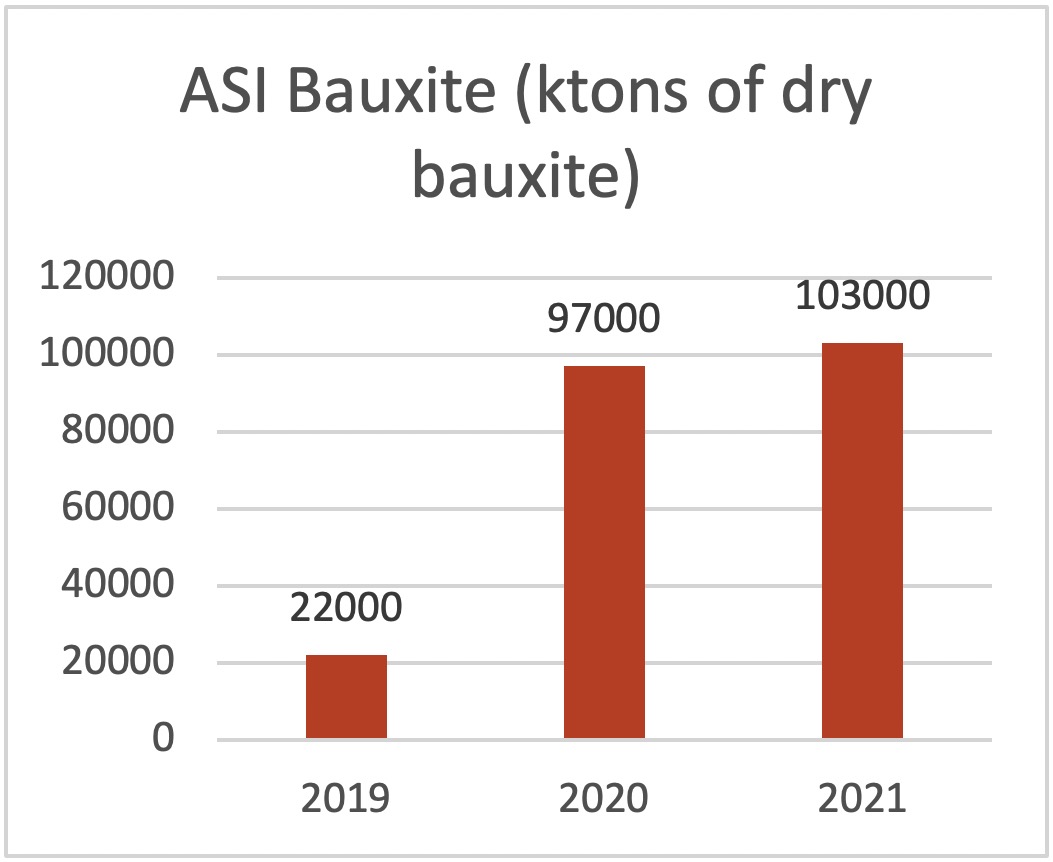

This data, representing the third year of data collection, showed an increase in volumes of CoC Material moving through the value chain and the number of CoC Certified Entities reporting. Previous years’ data showed around 50% attrition of CoC Material at each successive supply chain activity. However, in 2021, the “loss” of CoC Material flowing to non-certified Entities at each supply chain activity has decreased. While CoC Certified Bauxite Mines produced 103 million tonnes of ASI Bauxite (over 25% of global bauxite production), only around 70% of this material was supplied to CoC certified Alumina Refineries (making up 19% of total supplied Bauxite globally).

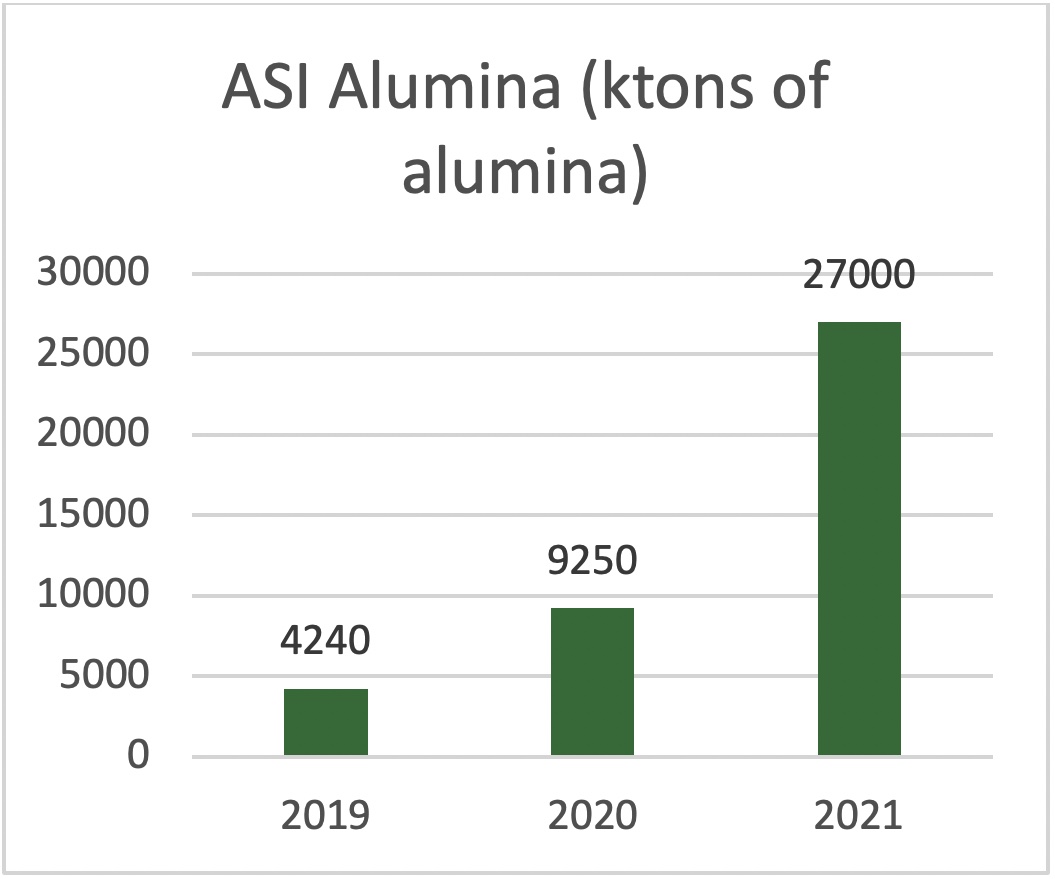

In turn 85% of the 27 Mt of Alumina produced by CoC Certified alumina refineries was shipped as ASI Alumina to CoC Certified Smelters, to produce ASI Aluminium.

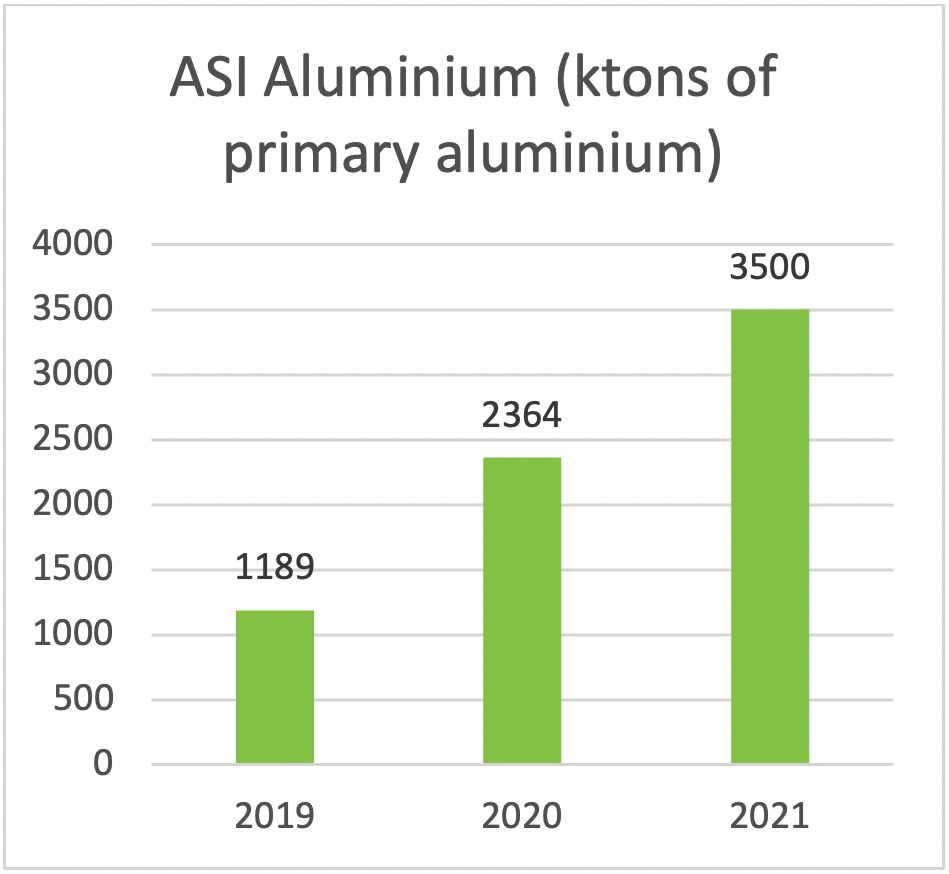

The 2021 data shows that the early uptake of CoC Certification at the bauxite mining and alumina refining stages has now flowed through to aluminium smelters. We anticipate that this will continue to extend through to successive supply chain steps in future, as downstream sourcing and procurement strategies continue to mature.

For the third year of CoC reporting, ASI incorporated changes in the data collection and analysis process

This year was the third annual data collection cycle for ASI Chain of Custody Material Flows. Changes to the data collection and analysis process included:

- Updates to the annual reporting criteria as set out in the 2022 CoC Standard

- Updates to the data visualisation method.

With the May 2022 launch of the revised CoC Standard, Entities were given a choice to report their CoC Material flows according to the 2017 or 2022 CoC Standard. For those reporting to the 2022 Standard, in addition to the CoC Material Inputs and Outputs, Entities were asked to provide quantities between supply chain activities within the boundaries of an Entity up to (and including) Smelters (termed as Intra-Entity Flows) and Non-ASI CoC Material entering and leaving the Certification Scope.

The majority of Entities found the new reporting easier and more aligned with their Material Accounting System and thus reported the volumes in line with the 2022 CoC Standard. With this data, ASI was able to review and detect inconsistencies in CoC Outputs more carefully, which were followed up. However, due to the self-reporting format, there are limitations in ASI’s ability to fully validate all data submitted. Auditors play a key role in periodic verification of Entity’s material accounting systems through surveillance and re-certification audits.

The alterations incorporated in the visualisation included removal of a calculated portion of ASI CoC Bauxite flowing to waste and inclusion of ASI Bauxite production. As the CoC Standard and allocation of CoC Material is based on the Mass Balance Model, Entities can choose where, within their Certification Scope boundaries, the material is transferred. Therefore, it is more appropriate to assign the complete share of CoC Material that lost its CoC status into Non-CoC Material which has moved down the chain rather than allocating it to waste. Due to these adjustments, which have been also applied to previous years’ data, production and flows of ASI CoC Bauxite have also changed for previous years. Previously the visualisation showed ASI Bauxite flow only to CoC Certified alumina refiners. The visualisation now represents the flow of ASI Bauxite from CoC Certified mines to both CoC and Non-CoC Certified refiners.

CoC Standard Version 2 introduced new terminology referring to all types of material entering, passing through, and leaving the boundaries of CoC Certified Entity, defined as Certification Scope and set up by a Member during the certification process:

Inputs/Outputs – CoC Material and/or Eligible Scrap purchased/sold from/to another CoC Certified Entities outside of an Entity’s Certification Scope

Intra-Entity Flows – transfer of the CoC Material between supply chain activities within an Entity’s Certification Scope (where the type of CoC Material is transformed and potentially Output mid-stream, allowing for the share of CoC Material to be mass balanced within the Entity), recorded from Bauxite Mine up to and including Aluminium Smelter.

Inflows/Outflows – general flow of all material (encompassing both CoC and Non-CoC and Intra-Entity Flows) into and out of an Entity and/or its supply chain activities

Year on year increase in availability of CoC Material at each supply chain activity along the aluminium value chain

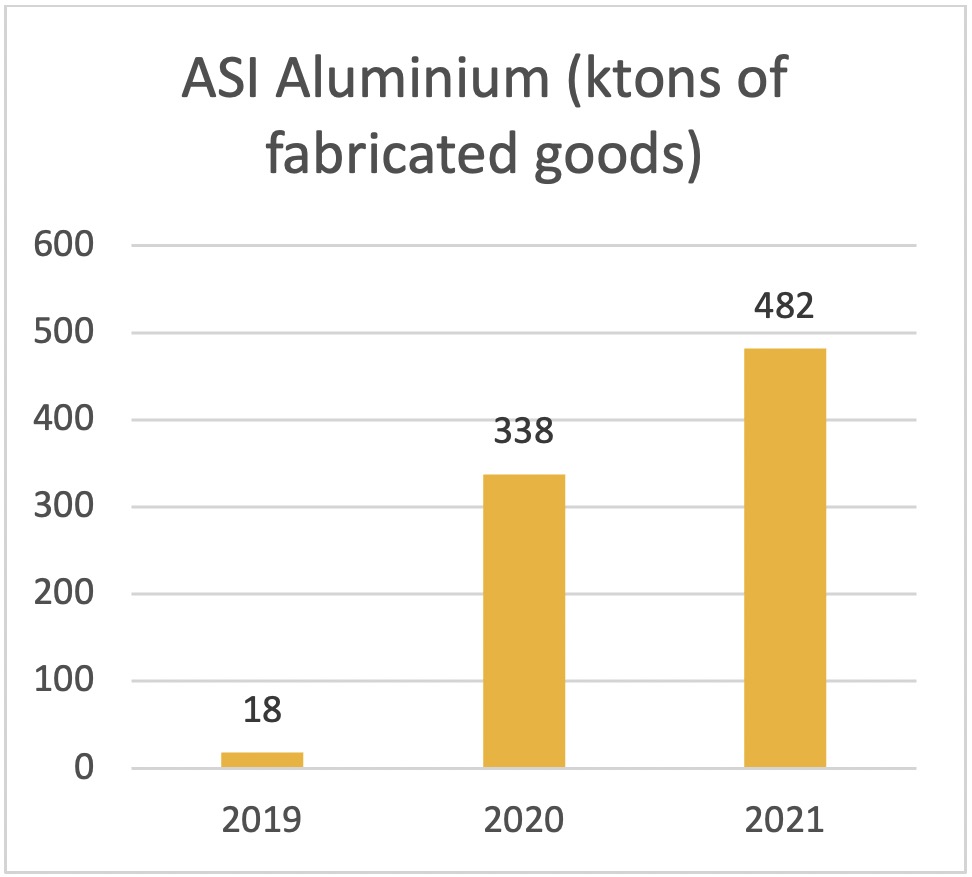

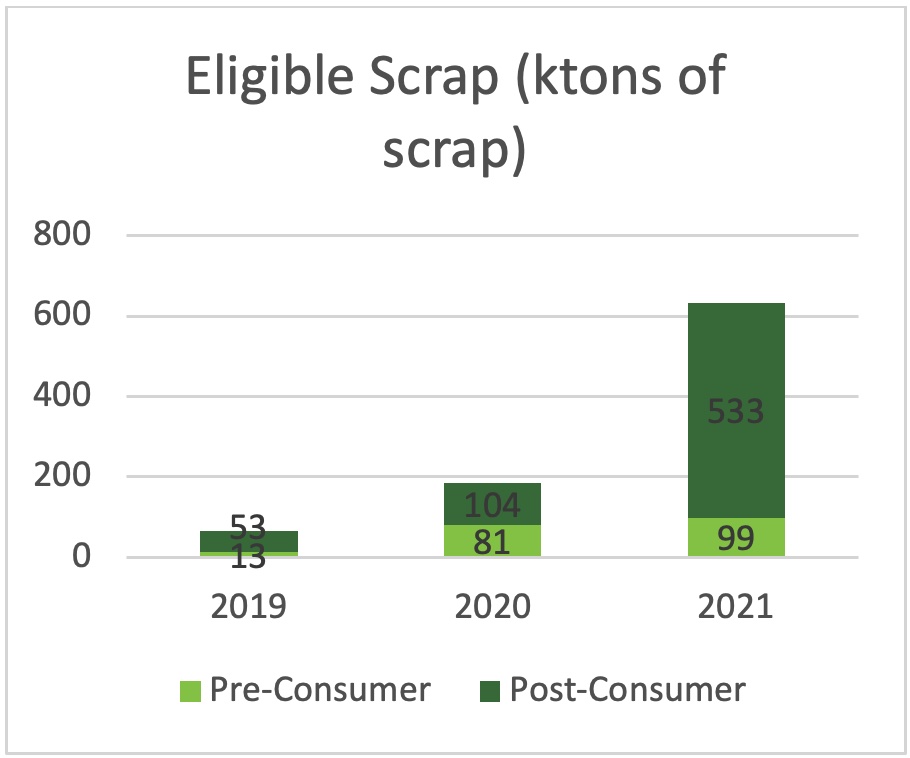

Volumes of CoC Material have been increasing each year for each type of the CoC Material (ASI Bauxite, ASI Alumina, ASI Aluminium, Eligible Scrap). The largest year-on-year increases so far have been for ASI Bauxite from 2019 to 2020, ASI Alumina from 2020 to 2021, fabricated ASI Aluminium from 2019 to 2020 and Eligible Scrap from 2020 to 2021 (expressed in volumes of material). Around 85% of Eligible Scrap in 2021 consisted of Post-Consumer Scrap (note: Pre-Consumer Scrap generated and remelted within the same Entity stays in the Entity’s closed loop, so is not required to be reported under CoC Standard and thus not included in the visualisation).

The 2021 data shows that the early uptake of CoC Certification at the bauxite mining and alumina refining stages has now flowed through to aluminium smelters. We anticipate that this will continue to extend through to successive supply chain steps in future, as downstream sourcing and procurement strategies continue to mature.

We sincerely thank IAI for their collaboration and support and all reporting CoC Certified Entities for their positive engagement.

For more information on ASI CoC Material Flows, contact Klaudia Michalska.

More information

SHARE THIS ARTICLE