ASI certifies Daiki Aluminium Industry Co., Ltd. against Performance Standard V3

The facility produces recycled scrap Ingots and recycled liquid metal using aluminium scraps as the main raw materials.

12 November 2024

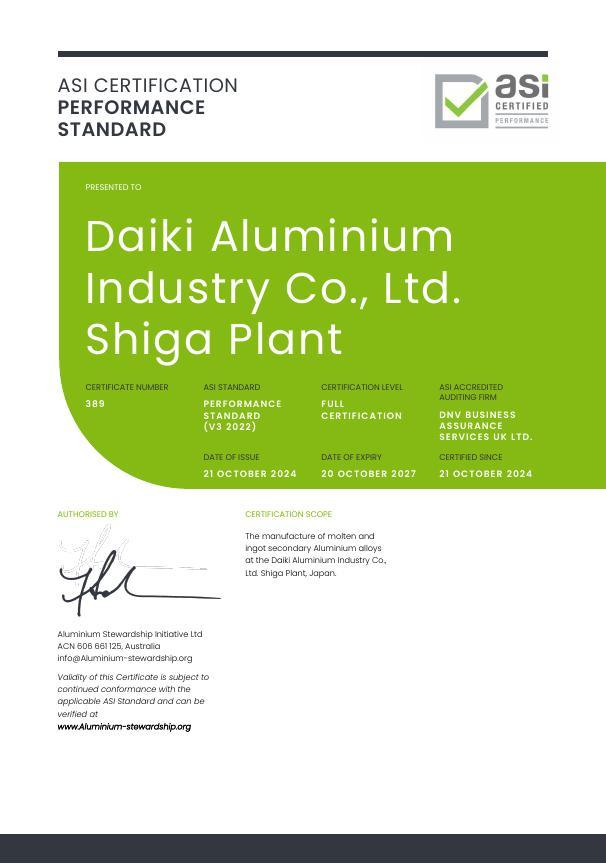

Aluminium Stewardship Initiative (ASI) today announced that Daiki Aluminium Industry Co., Ltd. has been certified against the ASI Performance Standard V3 (2022). The facility produces recycled scrap Ingots and recycled liquid metal using aluminium scraps as the main raw materials. The facility’s annual production capacity is approximately 38,500 metric tonnes. The plant is equipped with three melting furnaces, two rotary furnaces, casting equipment, molten metal transport equipment, and raw material pretreatment equipment.

Aluminium Stewardship Initiative (ASI) today announced that Daiki Aluminium Industry Co., Ltd. has been certified against the ASI Performance Standard V3 (2022). The facility produces recycled scrap Ingots and recycled liquid metal using aluminium scraps as the main raw materials. The facility’s annual production capacity is approximately 38,500 metric tonnes. The plant is equipped with three melting furnaces, two rotary furnaces, casting equipment, molten metal transport equipment, and raw material pretreatment equipment.

The ASI Certification program was developed through an extensive multi-stakeholder consultation process and is the only comprehensive voluntary sustainability standard initiative for the aluminium value chain. The ASI Performance Standard V3 (2022) was launched in May 2022 following a multi-year revision process. It defines 11 principles and 62 criteria under three sustainability pillars – Environment, Social, and Governance – with the aim to address pressing sustainability issues in the aluminium value chain, such as biodiversity, Indigenous Peoples’ rights, circularity, and greenhouse gas emissions.

The independent, third-party audit of Daiki Aluminium Industry Co., Ltd. was carried out by DNV Business Assurance Services UK Ltd. A full listing of audit findings outlining evidence of conformances and minor non-conformances is available from page 5 of the summary audit report, linked below. Four minor non-conformances are noted under 2.4a-e Responsible Sourcing, 5.1a-b Disclosure of GHG Emissions and Energy Use, 5.3a-e GHG Emissions Reduction Plans and 10.7a-d Remuneration. During the Certification Period, Daiki Aluminium Industry Co., Ltd. will be implementing a corrective action plan, which will be verified in follow-up audits.

More information

SHARE THIS ARTICLE