MinTa Aluminum Technology

MEMBER CLASS

Production and Transformation

JOIN DATE

March 2023

HEADQUARTER LOCATION

China

WEBSITE

https://www.mintatc.com

CERTIFICATIONS

About MinTa Aluminum Technology

MinTa Aluminum was established in 1961 in Tainan, Taiwan, and has since been continually dedicating efforts in metal processing for over half a century. Today, MinTa has the capability to provide customers with a complete solution in supplying aluminium profiles.The company was founded as a steel tube processing manufacturer for the bicycle industry. Engaging in the aluminium business by foreseeing the rising trend in using Aluminium, replacing steel and chromoly steel. By better serving our customers, MinTa started the Aluminium production sector in the new millennium. During the past decade, the company had a total investment reaching 30 million US dollars, successfully vertically integrated in aluminium profile procedures, which includes Aluminium Billet Casting, Die casting and tooling design in house, Aluminum Extrusion, CNC Milling in cutting, bending and punching, Surface Anodizing, and Hydroforming… etc. In order to achieve the best efficiency of cost and quality control, our one-stop service solution would bring down the opportunity cost during the communication process and maximise the benefits to customers. “Passion, Precision, and Perfection” have always been our team’s belief in delivering our customers with the satisfactory solution, over and above what we promised, to pursue the perfection of quality products also to carry on our long tradition of excellence. Our company is certified with ISO 9001-2008/IATF-16949 in the automobile industry, which approves our dedication to ensure quality products and services.

MinTa Aluminum is committed to meeting the high standards of the global aluminium industry. After becoming a member of ASI, MinTa Aluminum will accelerate carbon reduction, implement sustainable development and promote responsible production, including circular economy of recycled aluminium, to promote the sustainable development of the global aluminium industry.

- Shou Cheng Cheng, General Manager

Certifications

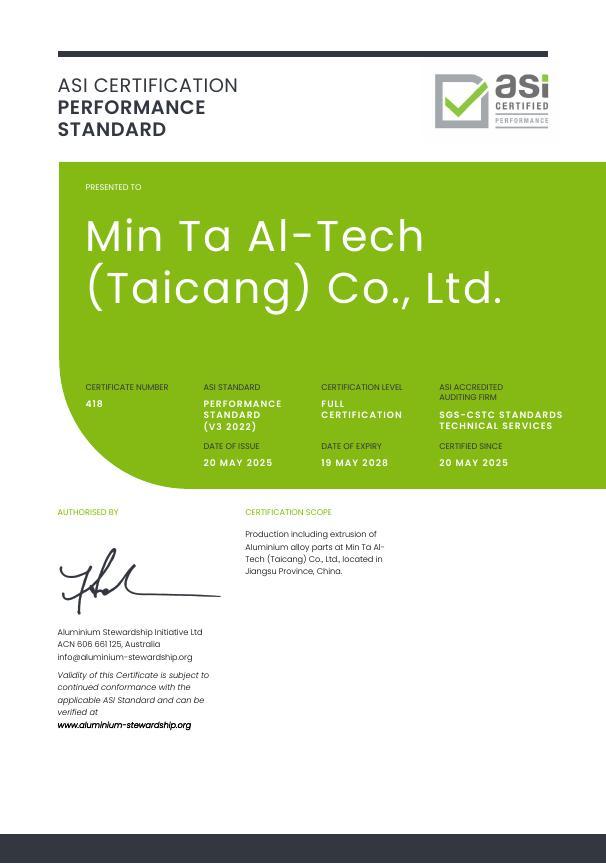

- Certificate Number: 418

- Certification Period: 20.05.2025 - 19.05.2028

- Audit Report

- Production including extrusion of Aluminium alloy parts at Min Ta Al-Tech (Taicang) Co., Ltd, located in Jiangsu Province, China.

- Semi-Fabrication

- Material Conversion

Additional Information

Activities in the aluminium value chain*

- Semi-fabrication (rolling, extrusion, casting)

- Aerospace - Product or component manufacturing (material conversion)

- Automotive - Product or component manufacturing (material conversion)

- Collection of post-use recyclable material

* may contain both ASI-certified and non ASI-certified

Countries of operation

Asia

- China

Other Production and Transformation Members

SHARE THIS PAGE: