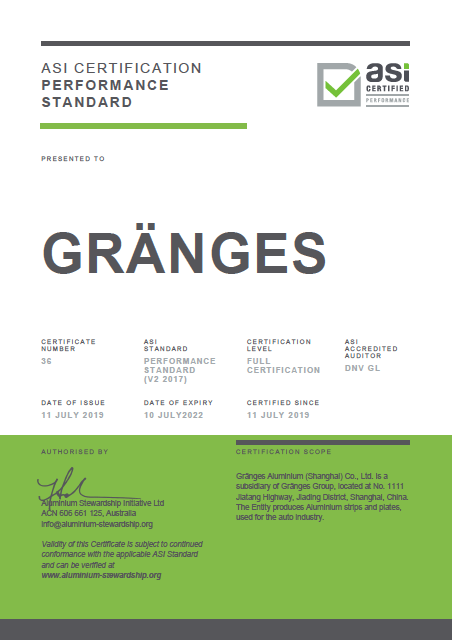

Aluminium Stewardship Initiative certifies Gränges against ASI Performance Standard

The company’s Shanghai operations outputs include aluminium strips and plates used for the auto industry.

16 July 2019

Aluminium Stewardship Initiative (ASI) today announced that Gränges’ Shanghai production plant has been successfully certified against ASI’s Performance Standard for responsible production, sourcing and stewardship of aluminium. The plant is set up for direct chill casting, hot rolling, cold rolling, and finishing, with a current production capacity of 120 ktonnes.

Aluminium Stewardship Initiative (ASI) today announced that Gränges’ Shanghai production plant has been successfully certified against ASI’s Performance Standard for responsible production, sourcing and stewardship of aluminium. The plant is set up for direct chill casting, hot rolling, cold rolling, and finishing, with a current production capacity of 120 ktonnes.

The ASI Certification program was developed through an extensive multi-stakeholder consultation process and is the only comprehensive voluntary sustainability standard initiative for the aluminium value chain. The independent, third-party audit of Gränges was carried out by DNV GL.

Fiona Solomon, Chief Executive Officer at ASI, said “Aluminium has clear lightweighting benefits that improve the environmental performance of vehicles, and responsible production practices in automotive supply chains is similarly important. Gränges’ Performance Standard certification demonstrates a leadership role to support and drive sustainability as an aluminium supplier to the automotive sector. We are also delighted to see that Gränges is the fourth company to achieve ASI certification of operations in China.“

Johan Menckel, Chief Executive Officer at Gränges, said “Achieving this ASI certification is an important milestone in our sustainability commitment and ambitious sustainability agenda and it is a great recognition for our sustainability efforts. The certification verifies that our aluminium products are produced responsibly and sustainably and it is a first step towards being able to offer certified aluminium products to our customers. It also provides assurance to our customers and other stakeholders that we are committed to meet the increased sustainability requirements. We now intend to achieve certification for our other facilities, to promote responsible production and sourcing practices in the aluminium industry.”

Consult the Gränges Summary Audit Report

SHARE THIS ARTICLE