Procurement Strategies for 1.5ºC Alignment: Short- and long-term challenges to secure lower carbon aluminium

For downstream Entities (aluminium transformers and fabricators), the majority of supply chain emissions reduction will be achieved through the implementation of procurement strategies. What are the challenges these businesses will face as they seek to mitigate the emissions embodied in the aluminium products they purchase?

10 June 2024

For downstream Entities (aluminium transformers and fabricators), the majority of supply chain emissions reduction will be achieved through the implementation of procurement strategies. What are the challenges these businesses will face as they seek to mitigate the emissions embodied in the aluminium products they purchase?

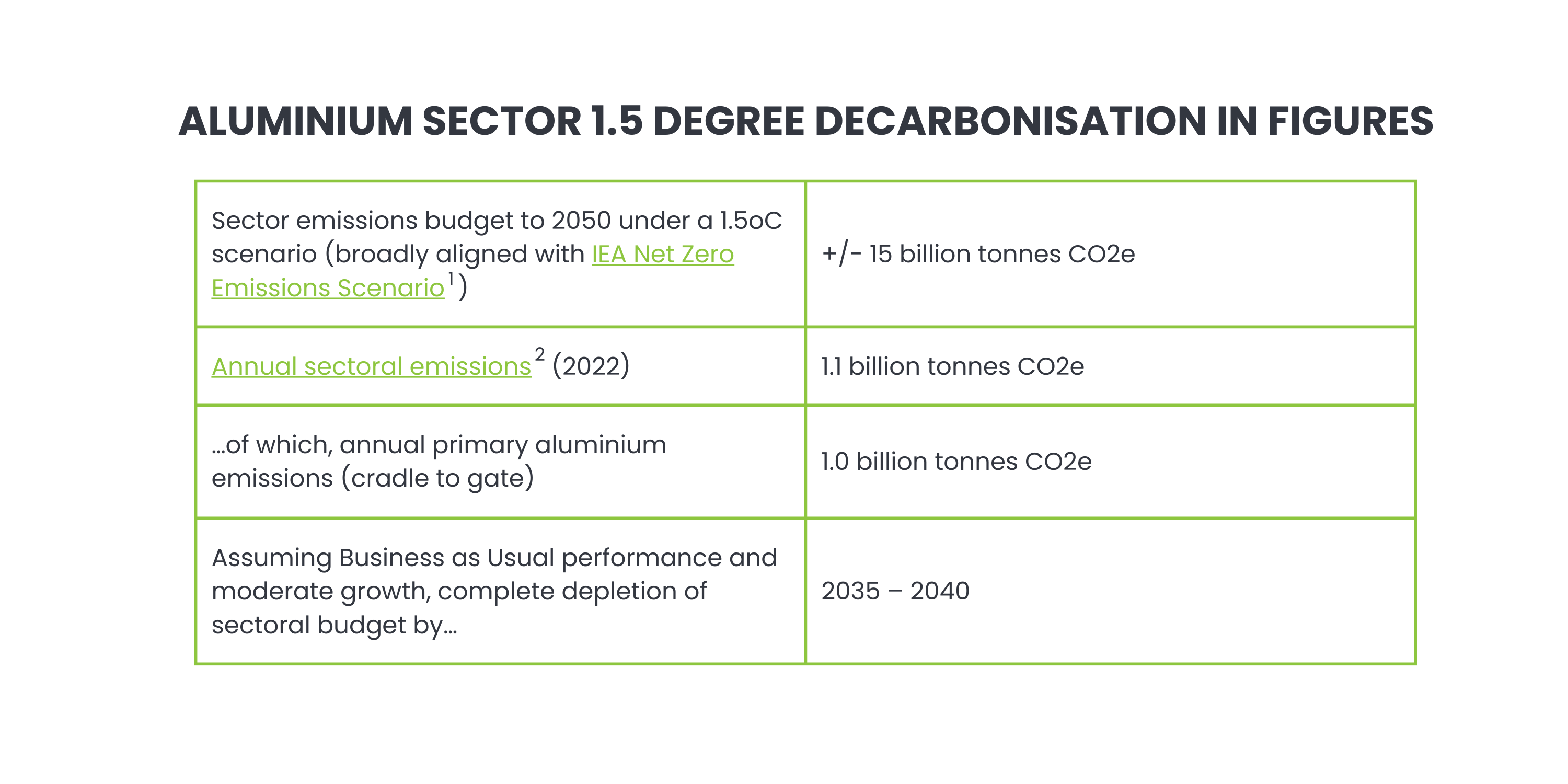

With most of the sector’s emissions concentrated in primary production processes, the success of efforts to follow a 1.5 degree aligned slope for their procured metal is dependent on companies’ ability to:

- source low(er) carbon or 1.5-aligned decarbonising primary metal;

- source scrap (of the required quality) or metal with higher recycled content;

- collaborate with other actors in the industry to moderate demand, through improved process efficiencies and design innovations, including through engagement with ASI’s Circularity Working Group and Framework.

To address point 1, downstream companies must navigate significant supply security constraints for lower carbon primary today and over the next two decades:

- the lowest carbon footprint primary metal in the world today is between 3 and 4 t CO2e/t Al – four times higher than it will need to be by 2050;

- sub 5 t CO2e/t Al represents only around 15 million tonnes (20%) of current primary supply;

- 4 million tonnes of this total is currently supplied by sources from which many downstream companies, exchanges and countries in the West are currently turning away;

- it will take time for primary producers to bring more low(er) carbon aluminium to market at scale, by raising capital, retooling the industrial base, developing novel technologies and securing long term supply of renewable electricity.

Given these facts, the importance to downstream Entities’ decarbonisation plans of sourcing scrap and/or high recycled content metal is clear. This was evident in the many discussions at the World Aluminium 2024 conference, which ASI co-hosted with CRU and the International Aluminium Institute.

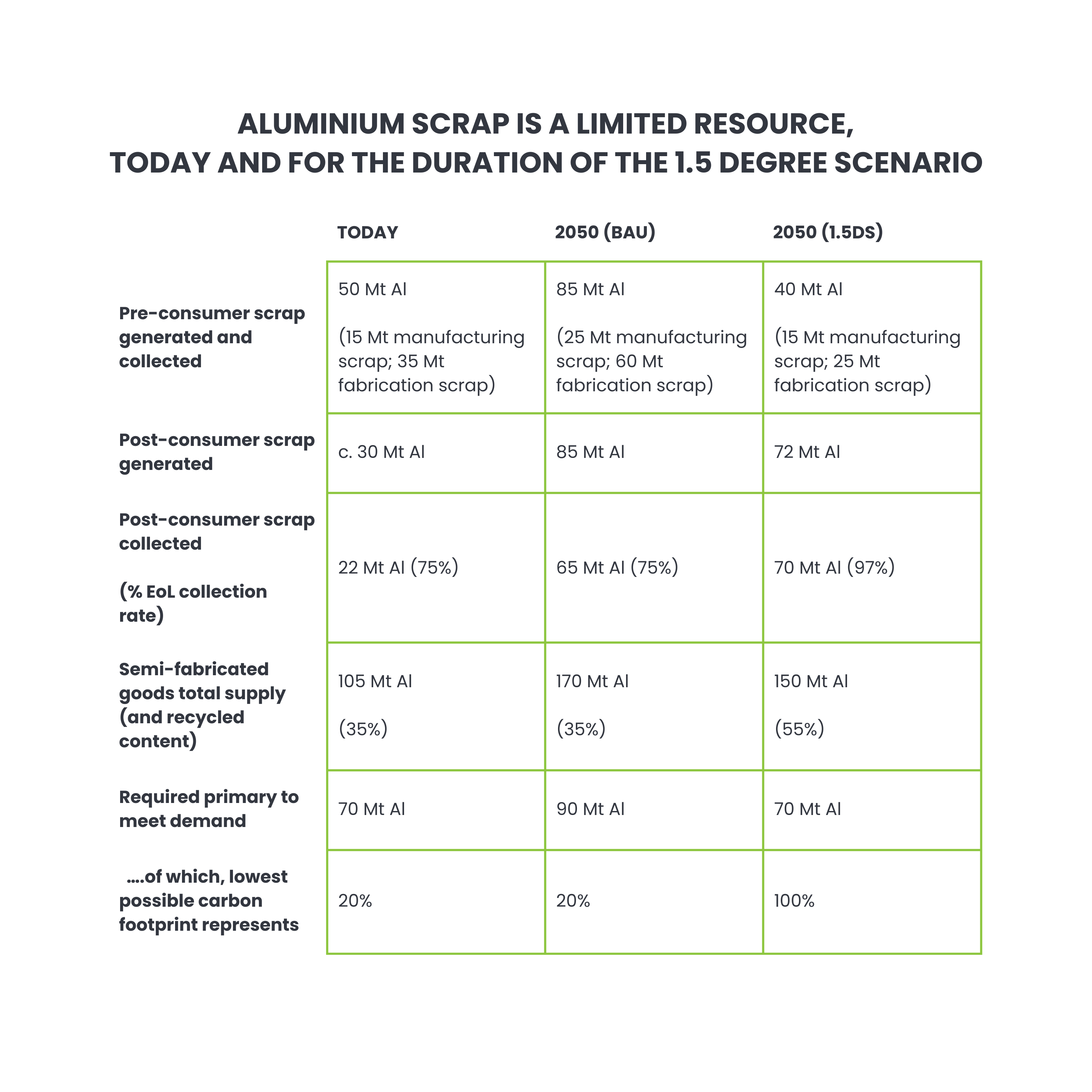

However, the quantity of scrap available to meet such needs is also limited and will remain limited until well into the second half of the 21st century.

Significant volumes of scrap, in the right place and with the necessary quality for user needs (not requiring complex and costly sorting and recovery processes) are and will be even more scarce.

The table to the right gives some figures to illustrate this, drawn from the International Aluminium Institute (IAI) Alucycle Model (2021 1.5 Degrees Scenario – Low Substitution) and 1.5 Degrees Scenario data.

Those Entities that are able to source low(er) carbon primary aluminium, volumes of quality, well sorted post-consumer scrap (e.g. used beverage cans or well segregated window frames) or pre-consumer scrap (already well segregated, high quality and near 100% collection rates), or the metal derived from such, are in a privileged position.

However, to continue to be 1.5ºC aligned these Entities will need even lower carbon footprint primary and/or more material with higher post-consumer recycled content.

Higher post-consumer recycled content because the generation of pre-consumer scrap DECREASES under a 1.5oC scenario, as manufacturers and their customers become more resource efficient. The challenge will therefore be on all Entities to secure (and maintain) security of supply by nurturing strategic relationships with suppliers, but also through the development of closed-loop systems in tandem with product design, exploring metal leasing business models and moderating demand by implementing more efficient manufacturing processes. These systemic changes to the ways that Entities do business are being explored by ASI’s Circularity Working Group, which is seeking to embed circular economy principles into existing and future iterations of the ASI Performance Standard (and Chain of Custody Standard).

The ASI Entity GHG Pathways Method also applies to downstream

Incorporation of reference to the ASI Method in the forthcoming Performance Standard Guidance v3.2 (2024) will see its use mandated for all Entities undergoing ASI Certification, to demonstrate conformance against Criterion 5.3 – GHG Emissions Reduction Plans.

For Certification Scopes incorporating Aluminium Smelting, the GHG Emissions Reduction Pathway is expressed as a Mine to Metal emissions intensity reduction slope, converging on the sectoral average of below one tonne of CO2e per tonne aluminium (cradle-to-gate) by 2050 – extremely challenging, almost four times lower than the lowest carbon primary available today and representing over 90% of the 15 billion tonne CO2e total aluminium sector carbon budget under a 1.5 degree aligned scenario.

However, Criterion 5.3 is not only applicable to Primary producers, but to all certifying Entities; thus the ASI Method also allows calculation of emissions reduction slopes for Remelting and Casting Supply Chain Activities, Semi-fabrication and Material Conversion.

All Supply Chain Activities downstream of Smelters are required to have a GHG Emissions Pathway for the aluminium they procure (in addition to Pathways for their own process emissions – GHG Protocol Scopes 1 & 2 – in the case of Casting and Semi-fabrication).

These take account of all emissions upstream to the point at which the Entity procures the metal and thus can incorporate both primary and recycled metal. The emissions intensity of this procured metal (measured at the input to the Entity or its processes) is broadly equivalent to the scope expressed by the following commonly used terms, albeit with some nuance:

- carbon footprint,

- embodied emissions,

- Mine to Metal input,

- GHG Protocol Scope 3 Category 1 for aluminium procured.

- BUT NOT cradle-to-gate as the process emissions are captured in another slope.

ASI’s Entity Level GHG Method makes no assumptions (nor prescription) about the source of aluminium being procured, nor its recycled content, but it does describe, for each Supply Chain Activity in the Entity Pathways scope, very aggressive emissions reduction (given the facts in the table to the right).

More information

For more information on the ASI GHG Entity Level Pathway Method, the emissions requirements of Performance Standard v3 for certifying Entities or strategies to meet 1.5 degree aligned reduction targets please contact ASI Climate Change and Decarbonisation Director, Chris Bayliss.

For more information on the ASI Circularity Working Group and Framework please contact ASI Circularity Research Manager, Dr Gabriel Carmona Aparicio.

Further details on the method and associated calculation tool, webinars and an educationAL online lesson can be found here.

SHARE THIS ARTICLE