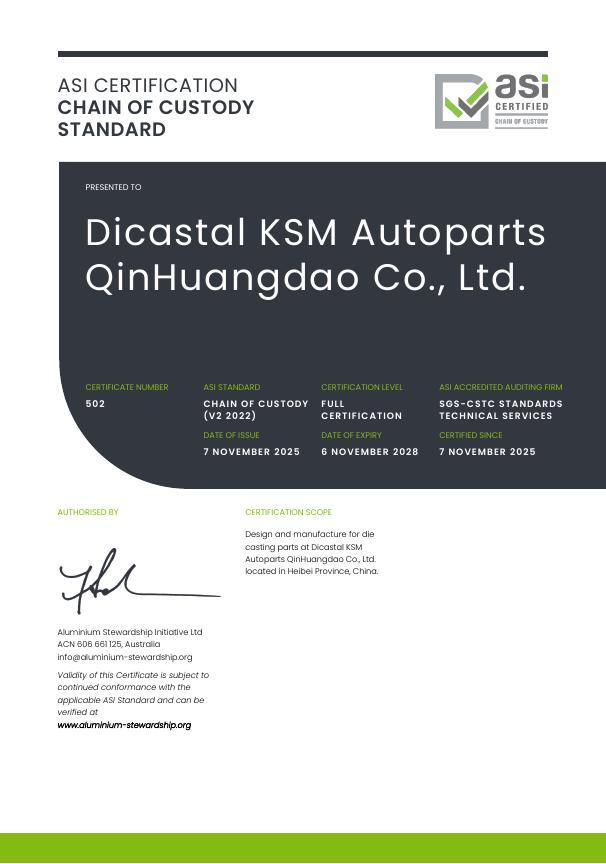

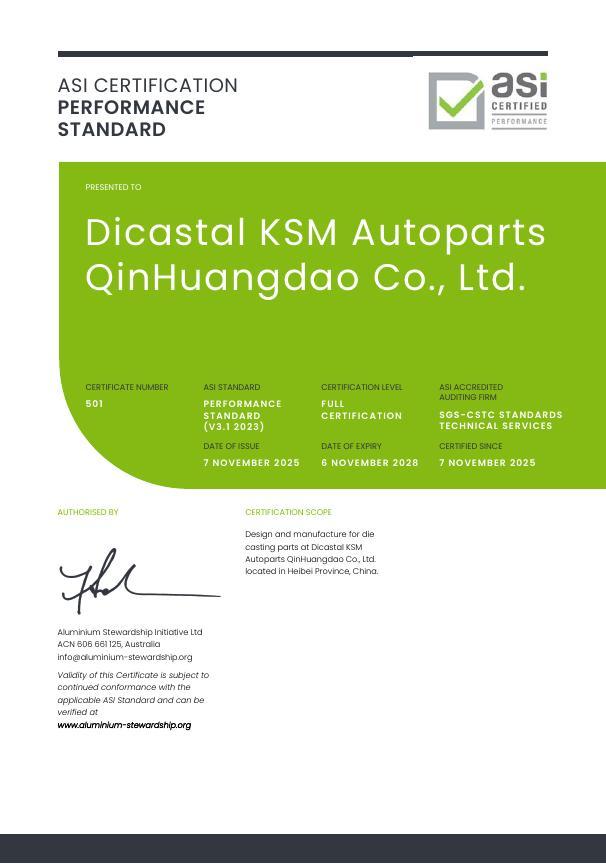

ASI certifies Dicastal KSM Autoparts QinHuangdao Co., Ltd. against Performance Standard V3.1 and Chain of Custody V2

The facility utilises high-pressure and differential-pressure casting processes to produce aluminium alloy automotive chassis components.

1 December 2025

Aluminium Stewardship Initiative (ASI) today announced that Dicastal KSM Autoparts QinHuangdao Co., Ltd. has been certified against the ASI Performance Standard V3.1 and Chain of Custody Standard V2. The facility utilises high-pressure and differential-pressure casting processes to produce aluminium alloy automotive chassis components, including steering knuckles, control arms, and wheel brackets, with an annual output of up to 4.4 million items across its production lines. Its operations encompass smelting, casting, heat treatment, machining, assembly, and shipping for major automotive customers.

The ASI Certification program was developed through an extensive multi-stakeholder consultation process and is the only comprehensive voluntary sustainability standard initiative for the aluminium value chain. The ASI Performance Standard V3 and ASI CoC Standard V2 were launched in May 2022 following a multi-year revision process. The 2022 Standards and related documents underwent a minor update in 2023, accounting for editorial changes, correction of minor errors and for general clarification, culminating in the release of Performance Standard V3.1 (2023) and Chain of Custody Standard V2.1 (2023).

The ASI Performance Standard defines 11 principles and 62 criteria under three sustainability pillars – Environment, Social, and Governance – with the aim to address pressing sustainability issues in the aluminium value chain, such as biodiversity, Indigenous Peoples rights, circularity, and greenhouse gas emissions. The ASI CoC Standard sets out requirements for the creation of a Chain of Custody for material that is produced and processed through the value chain into diverse downstream sectors. The implementation of ASI’s CoC Standard links verified practices at successive steps of the supply chain – certified under the ASI Performance Standard – to the products produced by ASI Certified Entities. The CoC Standard also confirms that appropriate policies and due diligence process are in place to identify and address critical issues, such as corruption, human rights abuses, materials originating from conflict-affected and high-risk areas in the supply chain and support responsible sourcing.

The independent, third-party audit of Dicastal KSM Autoparts QinHuangdao Co., Ltd. was carried out by SGS-CSTC Standards Technical Services. A full listing of audit findings outlining evidence of conformances and minor non-conformances is available from page 5 in each of the summary audit reports, linked below. Seven minor non-conformances were noted during the Performance Standard Certification audit, under Criteria 3.1a-b Sustainability Reporting, 4.1b-c Environmental Life Cycle Assessment – Disclosure, 6.5a-c Waste Management and Reporting, 9.2a-e Gender Equity and Women’s Empowerment, 10.3a-c Forced Labour, 10.8a-c Working Time and 11.1a Occupational Health and Safety (OH&S) Management System. During the Certification period, Dicastal KSM Autoparts QinHuangdao Co., Ltd. will be implementing a corrective action plan, which will be verified in follow-up audits. No non-conformances were identified during the Chain of Custody Certification audit.

More information

SHARE THIS ARTICLE