Adopting ISO 59000: A Guide to Circular Practices in the Aluminium Industry

The ISO 59000 family marks a significant step forward in promoting circular economy principles within the aluminium value chain. By embracing these standards, the aluminium industry can enhance resource efficiency, reduce waste, and create more sustainable production methods.

30 July 2024

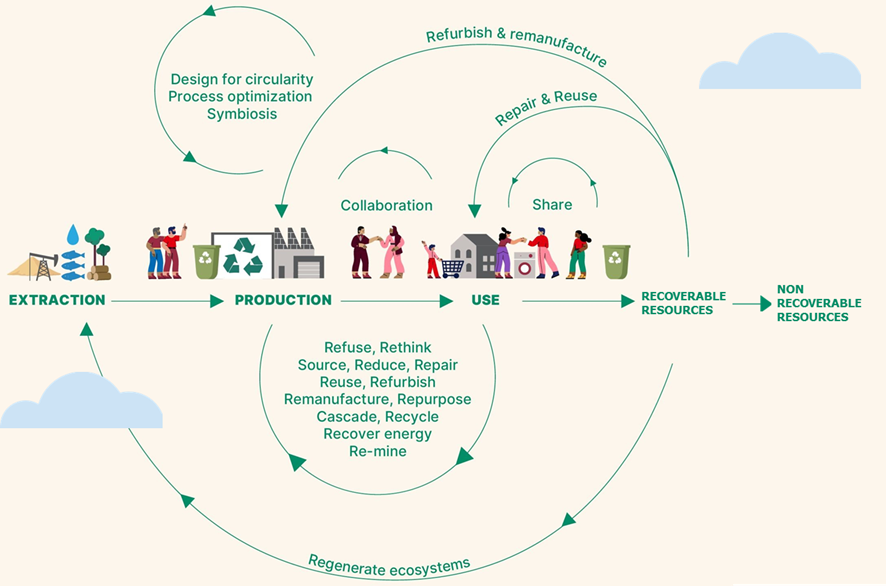

The circular economy is a restorative and regenerative model designed to keep products, components, and materials at their highest utility and value. Unlike the traditional linear economy, which follows a take-make-waste approach, the circular economy emphasizes resource efficiency, waste reduction, product life extension, and closed-loop systems. This model is particularly relevant to the aluminium industry, which faces increasing demand and the challenge of managing end-of-life materials. As we shift towards a circular economy, the aluminium industry must adopt strategies and practices that maximize resource utilization and minimize environmental impact, such as the ones promoted by the ISO 59000 family standards.

ASI collaborates with ISO as a liaison organization to ISO/TC 323 “Circular Economy”, to highlight the aluminium industry’s unique challenges whilst considering the opportunities through its sustainability standards. The collaboration between ASI and ISO aims to develop more sustainable practices.

Figure 1. ISO 59000 approach to Circular Economy. Source: ISO

The ISO 59000 family: An overview

The ISO 59000 family provides a harmonized international framework to help companies implement circular economy practices aligned with six principles: systems thinking, value creation, value sharing, resource stewardship, resource traceability, and ecosystem resilience. On 22nd May 2024, three core standards were published:

- ISO 59004: This primary standard offers vocabulary, principles, and actionable guidelines for any company aiming to transition to a circular economy. It defines key terms, outlines a vision for circularity, and provides core principles for sustainable resource management.

- ISO 59010: Focused on the execution and implementation of circular business models, this standard guides companies in assessing their current value creation models and developing strategies for circularity. It emphasizes business strategies and levers for implementing circular economy practices at both company and inter-company levels (i.e., value networks).

- ISO 59020: This standard provides a comprehensive framework for measuring and assessing circularity performance. It outlines core circularity indicators and guides companies in monitoring resource flows and sustainability impacts, aligning closely with the Sustainable Development Goals (SDGs).

Implementing ISO 59000 in the aluminium industry

The transition to a circular economy requires a strategic approach. Here’s how companies in the aluminium value chain can implement the ISO 59000 standards:

- Conduct a thorough assessment: Evaluate current practices, map resource flows, and identify potential areas for improvement. This step is critical for understanding the company’s unique context and setting realistic goals. Examples include using life cycle sustainability assessments, material flow analysis, and Sankey diagrams.

- Define clear objectives: Align circular economy initiatives with broader sustainability targets, such as the SDGs. Clear objectives help integrate circular practices into the core business strategy. Objectives may include value recovery, retaining resource value, and increasing supply chain traceability.

- Develop an action plan: Establish specific targets, allocate resources, and define roles and responsibilities. An actionable plan ensures that circular economy principles are systematically implemented across the organization. Actions might include circular sourcing and procurement, reverse logistics, circular product design, and ecosystem regeneration.

- Monitor and measure progress: Use relevant key performance indicators and data collection processes to track progress. Continuous monitoring enables companies to identify areas for further optimization and improvement. Indicators could include the average reused content of inflows or outflows, material productivity, average product or material lifetime relative to industry average, and design cyclability.

- Engage stakeholders: Foster collaboration and transparency among all stakeholders, including suppliers, customers, and employees. Effective communication and capacity building are essential for successful implementation. Examples of value networks include scenarios where a neutral, independent organization helps to establish and manage collaborative alliances within the industry. For instance, the aluminium recycling initiative in the window and curtain walling industry is facilitated by a non-profit organization that brings together around 180 member companies. This body coordinates efforts, shares best practices, and ensures that all members work towards common goals of enhancing recycling processes, improving material efficiency, and minimizing waste, thus promoting circular economy principles across the network.

Overcoming misconceptions

A common misconception about the circular economy is the overemphasis on recycling, often referred to as “recycling tunnel vision”. While recycling is an important component, the circular economy extends far beyond it. It involves rethinking and redesigning the entire lifecycle of products, from design and production to end-of-life management. By focusing on strategies that extend the lifespan and maximize the utility of products and materials, companies can achieve greater sustainability.

Future standards and innovations

The ISO 59000 family is just the beginning. Upcoming standards like ISO 59040 on product circularity data sheets and ISO 59014 on sustainability traceability of secondary materials will further enhance the circular economy framework. These standards will provide additional tools for improving circularity data sharing and ensuring the responsible recovery of secondary materials.

ASI’s role in promoting ISO 59000

As a liaison organization to ISO/TC 323 “Circular Economy”, ASI ensures that the aluminium industry’s unique challenges and opportunities are considered in the development of these international standards. By collaborating with ISO, we aim to drive the industry towards more sustainable practices, benefiting not only the environment but also the economy and society at large.

Join the movement towards a circular economy

The launch of the ISO 59000 family is a significant milestone in the journey towards a circular economy. For the aluminium industry, these standards offer a comprehensive and practical framework for enhancing sustainability. For more information on the ISO 59000 family development, join ASI’s Circularity Working Group – contact Gabriel Carmona Aparicio, ASI Circularity Research Manager

By working together, we can drive meaningful progress in sustainable circular practices within the aluminium industry.

RELATED TOPICS:

SHARE THIS ARTICLE